Customer Success Stories

It's our honor to serve you! Every compliment is valuable to us. Thank you for helping make ServiceJDC better and better.

The manufacturing service industry faces numerous challenges. In addition to the long-term task of rebranding itself through smart manufacturing and digital transformation to move away from its traditional image, how can it maintain stable operations amidst global productivity instability, labor shortages, transportation bottlenecks, delivery delays, shifting international dynamics, and the ongoing Russia-Ukraine conflict in the wake of the pandemic? Defeng Huang, General Manager of Kyoden, believes that the key to overcoming these challenges in the post-pandemic era is taking decisive action by implementing digital management tools.

Digital Transformation of Manufacturing Services Industry Begins with Digitalized Business Management Process

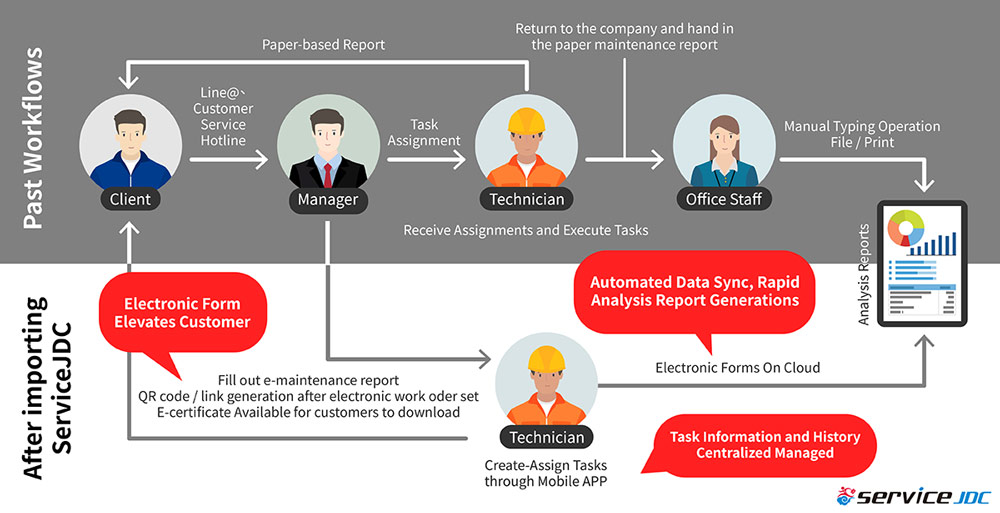

Trusted by international manufacturers and driven by a mission to enhance after-sales service, Kyoden embraced the shift toward remote communication and digital efficiency—accelerated by the pandemic—and chose to implement MDS’s ServiceJDC platform in 2021, according to Huang.

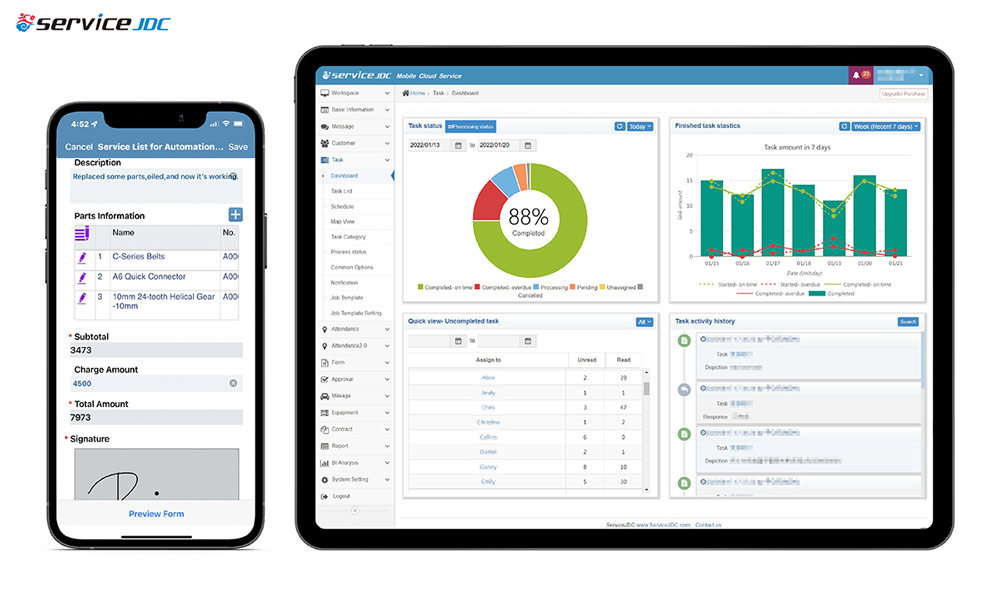

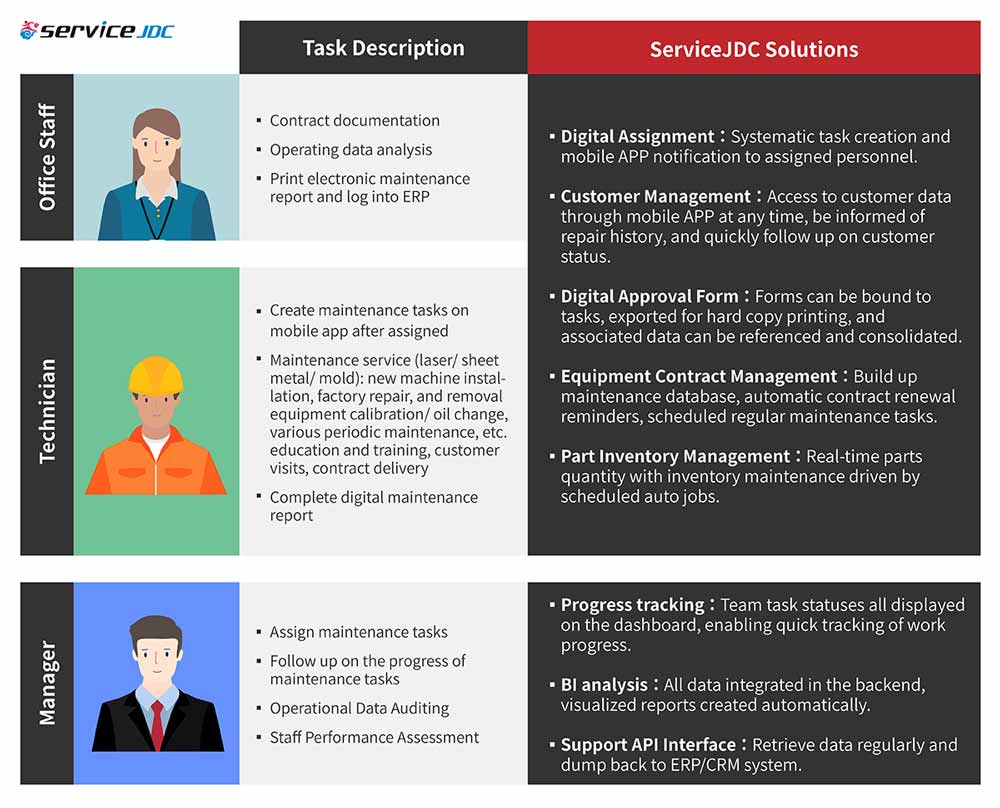

ServiceJDC, developed by MDS (Mercuries Data Systems, 2427), is designed to lead enterprises into a new era of efficient mobile office operations. It excels in enabling field staff to clock in and out across various platforms, report tasks, submit digital approval forms, and manage customers, sales, equipment maintenance, and contracts. With built-in support for statistical analysis and centralized cloud-based information management, ServiceJDC empowers businesses to achieve digital operations, refined management, and intelligent data analysis.

ServiceJDC Empowers Manufacturing Industries: Inventory Control, Regular Maintenance Reminders, Constructing Digital Service History

Mr. Huang said that ServiceJDC were now fully adopted, including technicians and managers. With ServiceJDC's real-time statistics, the company can monitor its part inventories and arrange deliveries in advance, even during epidemic, a delay in delivery, or a global logistics disruption caused by events like Russia-Ukraine conflict.

In addition, we are looking forward to integrating ServiceJDC with more management services in the future, for example, setting automatic reminders directly for customers' regular maintenance, or even calling out service history data through ServiceJDC to browse customers' maintenance frequency, parts requirements, purchasing suggestions, etc. during contract renewal and exchange.

ServiceJDC provides a full range of management solutions, including online attendance, task assignment, digital forms sign-off, customer management, equipment contract management, BI analysis and other functions. ServiceJDC has been trusted by more than 9,000 enterprises, including food retail, automated equipment maintenance, mechanical and electronic equipment agents, merchandizing display, food and beverage franchise, cleaning services, building construction, air conditioning and electrical engineering, finance and insurance, medical materials and long-term care services. We provide the most professional one-on-one consulting services for enterprises to help enterprises to achieve digital mobile operation, face the epidemic more easily, and quickly in response to various office models. ServiceJDC is free to use up to five users, learn more on ServiceJDC official website.