The electronics industry involves complex, high-precision equipment, making in-factory safety inspections essential for protecting workers and ensuring smooth operations. According to Article 23 of the Occupational Safety and Health Act, employers must establish safety management plans and assign dedicated personnel. Regulations also require regular and focused machinery inspections, with customized checklists based on the worksite. All inspection records must be stored for at least three years for audit purposes. Proper inspection not only ensures compliance but also helps prevent accidents and production disruptions, highlighting the importance of systematic and well-documented patrol inspections in modern electronics manufacturing.

Conventional paper-based inspections are time-consuming and prone to errors or omissions. Sharing results with managers is slow, and manual data entry into Excel delays analysis, undermining real-time responsiveness and data accuracy. This inefficiency prevents inspection data from truly supporting operations. ServiceJDC’s smart patrol and e-form features solve these issues by streamlining the entire process—enabling faster, more accurate, and more efficient patrol inspection management in factories.

ServiceJDC Smart Patrol Inspection: A Green Shift from Paper-Based to Digital Documentation

For patrol inspectors in the electronics industry, daily tasks such as attendance check-in, routine equipment and environmental inspections, contractor work permit application and approvals, and equipment maintenance or repairs all involve form submissions. By digitizing these forms and approval processes, ServiceJDC enables the electronics industry to fully digitalize operations related to attendance, inspections, and maintenance. Combined with task, equipment, and scheduled automation modules, over 80% of business processes can be streamlined—resulting in faster workflows and more immediate, transparent information sharing.

I. Attendance Scenarios: Law Compliant, Efficiency Boosted

ServiceJDC enables electronics companies to implement mobile attendance management for clock-ins/outs, leave requests, overtime applications, and multi-shift scheduling. Employees can conveniently use the mobile app to clock in via GPS, Wi-Fi, or NFC, check their schedules, and submit leave or overtime requests. Attendance data is uploaded in real-time, with automated work hour calculations. Managers can access team clock-in records and approve attendance and leave forms through the web or app—greatly reducing the administrative burden on managers and HR while improving overall efficiency.

II. Patrol Inspection Scenarios: Inspection Management Firmly Implemented, Labor Safety Upgraded

1. Automated Patrol Inspection – NFC Check-ins, auto-linked to patrol checklist

Given the diverse equipment and inspection needs in electronics factories, ServiceJDC offers flexible form and signature customization, simplifying the digitization process. Businesses can easily create tailored inspection forms for different factory zones and equipment types—covering everything from environmental checks and machinery to fire safety and first-aid equipment.

After creating the forms, users can define inspection locations and routes in the Patrol Inspection module. By setting daily, weekly, monthly, or yearly tasks with the auto-scheduling feature, routine inspections can be generated automatically. Patrol staff or safety personnel can simply scan an NFC tag (or QR code) to load the relevant form, significantly boosting efficiency and inspection quality.

More importantly, all inspection data is instantly synchronized to the system, enabling managers to monitor factory status in real time, ensure transparent oversight, and quickly identify and address potential issues.

2. Contractor Operation Forms – Mobile Submission, Instant Approval

In electronics factories, contractors often need to enter for construction or maintenance work. With ServiceJDC’s Approval Management feature, contractors can submit work permit application via mobile app. Safety personnel receive instant notifications for review and approval. Environmental safety checklists are also digitized, allowing staff to complete forms directly on the app. This streamlined process reduces labor and time costs while enabling safety teams to focus on quality and compliance.

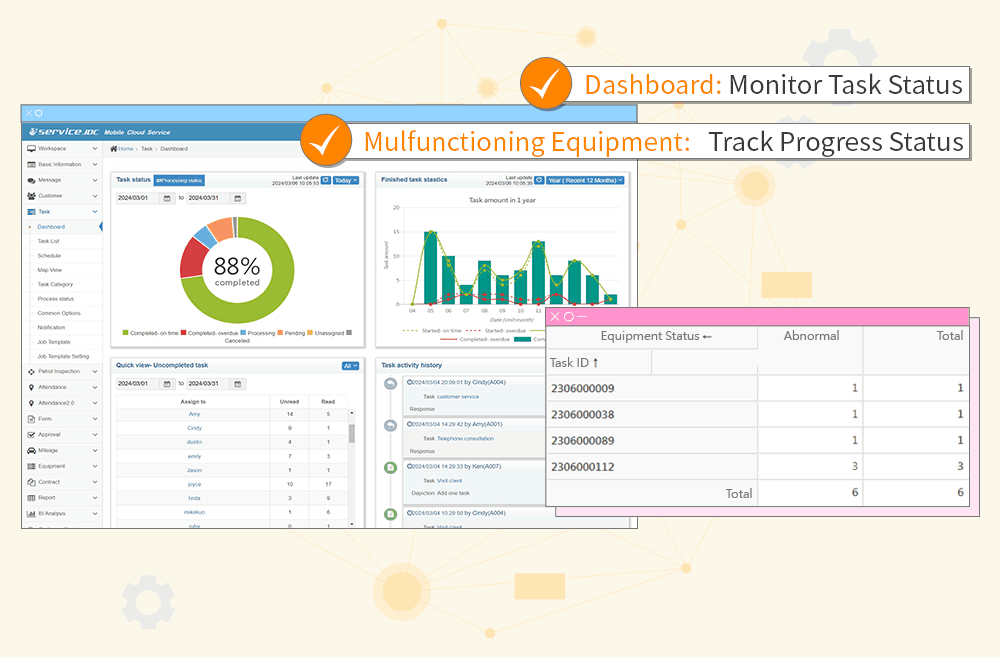

III. Repair Scenarios: Systematic repair history, equipment dependability upgraded

Stable equipment operation is essential for factory productivity, and regular maintenance plays a key role. With ServiceJDC, scheduled maintenance tasks can be auto-generated just like inspections. When abnormalities are found during inspections, personnel can instantly create repair tasks via the APP, assign them to maintenance staff, and track the repair process in real-time. All the records including time, personnel, and details—is stored for easy reference. This ensures clear oversight of equipment status, promotes long-term stability, and minimizes losses from unexpected breakdowns.

ServiceJDC's Powerful Digital Transformation: Empowering 9,000+ Enterprises to Focus on Core Value and Maximize Efficiency

Digitalization is no longer a slogan—it’s an essential step forward. ServiceJDC’s Smart Patrol Inspection System revolutionizes traditional paper-based processes in electronics factories, streamlining workflows, enhancing efficiency, and supporting green, sustainable operations. It's not just a trend, but a necessity for future-ready factory management. Join the movement toward smarter operations—register with ServiceJDC today and let our expert consultants tailor the right solution for your business needs.